How might we redesign the Core500 stethoscope eartips to ensure a reliable, acoustic seal cross various ear anatomies while maintaining comfort and durability for long-term use?

Eko Health

Invention Corps of Berkeley Contract

Kayla Reid, Meghna Sharma, Sravya Bandla, Conor McSeveney, Erin Pan, Kevin Wong, Zoe Petty

Current State

Eko’s current stethoscope eartips have notable quality and functionality issues.

-

Over long periods of wear, users report specific sections that ache. The current design doesn’t accomodate multiple ear canal shapes and sizes.

-

The eartips detach too easily from the stethoscope stem, often caused by the addition/removal of the stethoscope to a doctor’s neck.

Mission

How might we redesign the Core500 stethoscope eartips to ensure a reliable, acoustic seal cross various ear anatomies while maintaining comfort and durability for long-term use?

Stage 1: Research

Project Phases

Checkpoint: CAD Critique

Stage 2: Ideation (Sketching, CAD)

Checkpoint: Acoustic Testing

Stage 3: Rapid Prototyping (Injection Molding)

Final Deliverables

Stage 1: Research

Competitive Analysis

Internal Testing

Anthropometry

Lee, Wonsup, et al. “Anthropometric Analysis of 3D Ear Scans of Koreans and Caucasians for Ear Product Design.” Ergonomics, vol. 61, no. 11, 2018, pp. 1480–1495. PubMed+2Taylor & Francis Online+2

Song, Haseung, Gee Won Shin, Yeree Yoon, and Sangwoo Bahn. “The Effects of Ear Dimensions and Product Attributes on the Wearing Comfort of Wireless Earphones.” Applied Sciences, vol. 10, no. 24, 2020, article 8890. ResearchGate

Japatti, Sharanbasappa R., Priyanka J. Engineer, Manjunatha Reddy B., Akash U. Tiwari, Chidambar Y. Siddegowda, and Reshma B. Hammannavar. “Anthropometric Assessment of the Normal Adult Human Ear.” Annals of Maxillofacial Surgery, vol. 8, no. 1, 2018, pp. 42–50.

Stage 2: Ideation

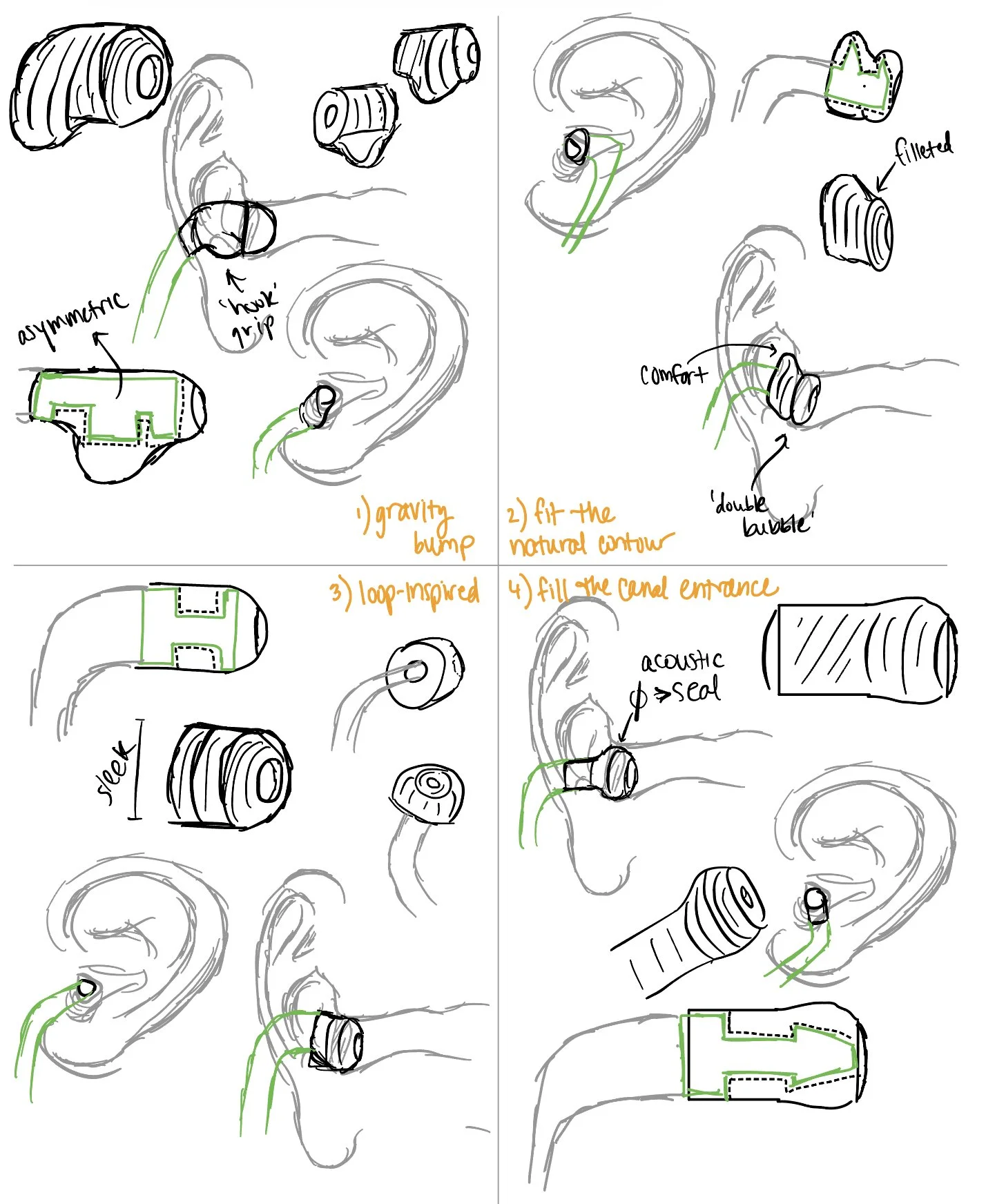

Individual and Team Sketching

my initial 4 ideas

Team Designs: Iteration 1

External Usability Testing & Internal Weighted Matrix

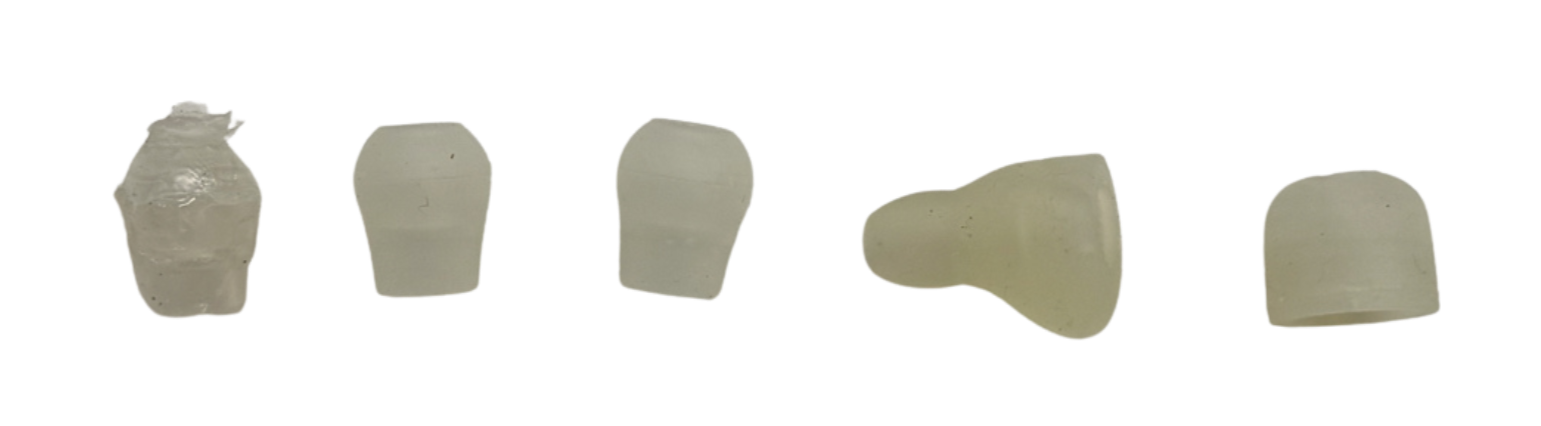

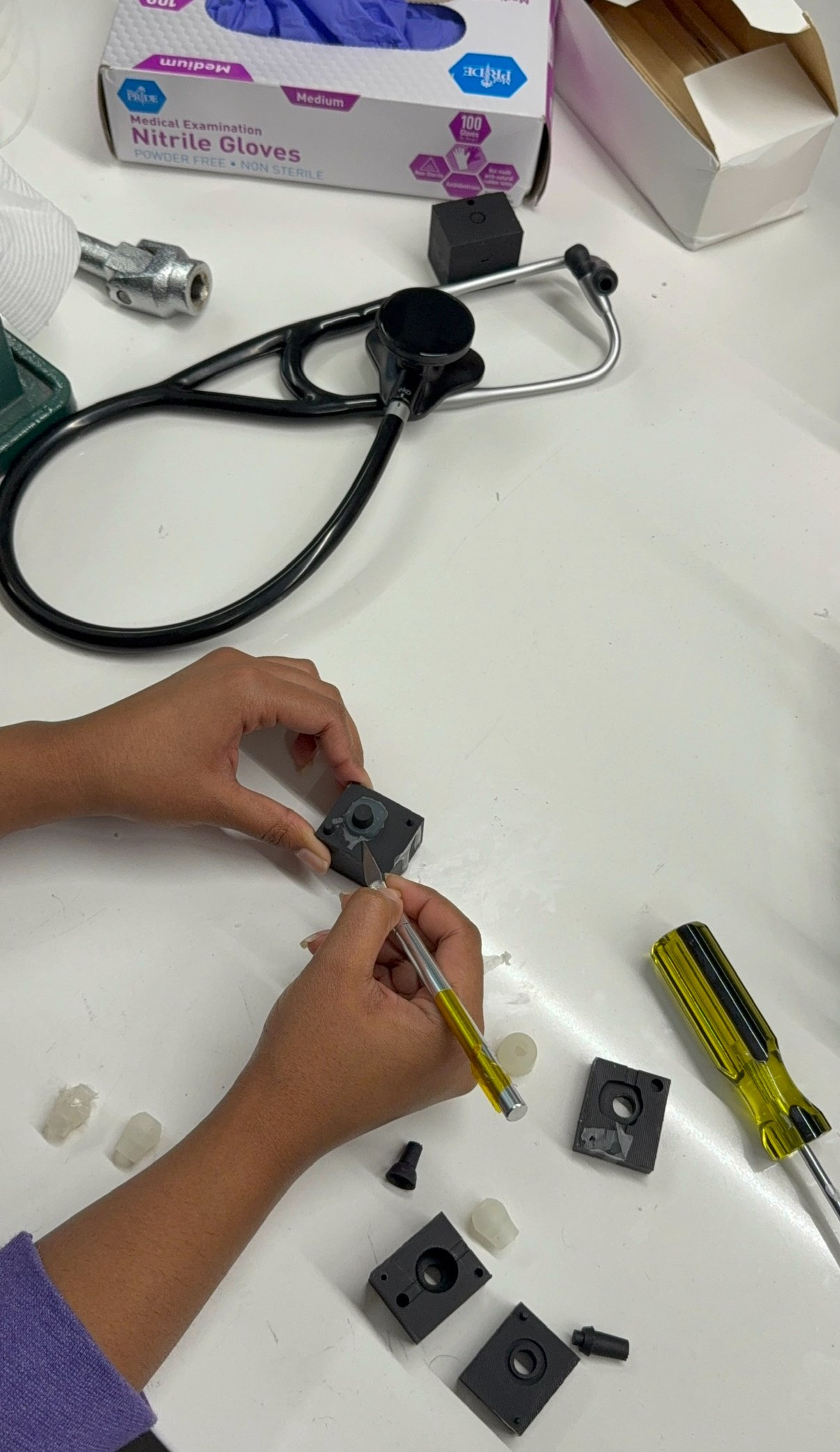

Testing: Rapid Prototyping

using TC-5150 A/B Translucent Silicone Rubber (vulcanized, a strain hardening technique)

Criteria: Comfort, Fit, Manufacturability, Material Compatibility, Acoustic Seal, Aesthetics

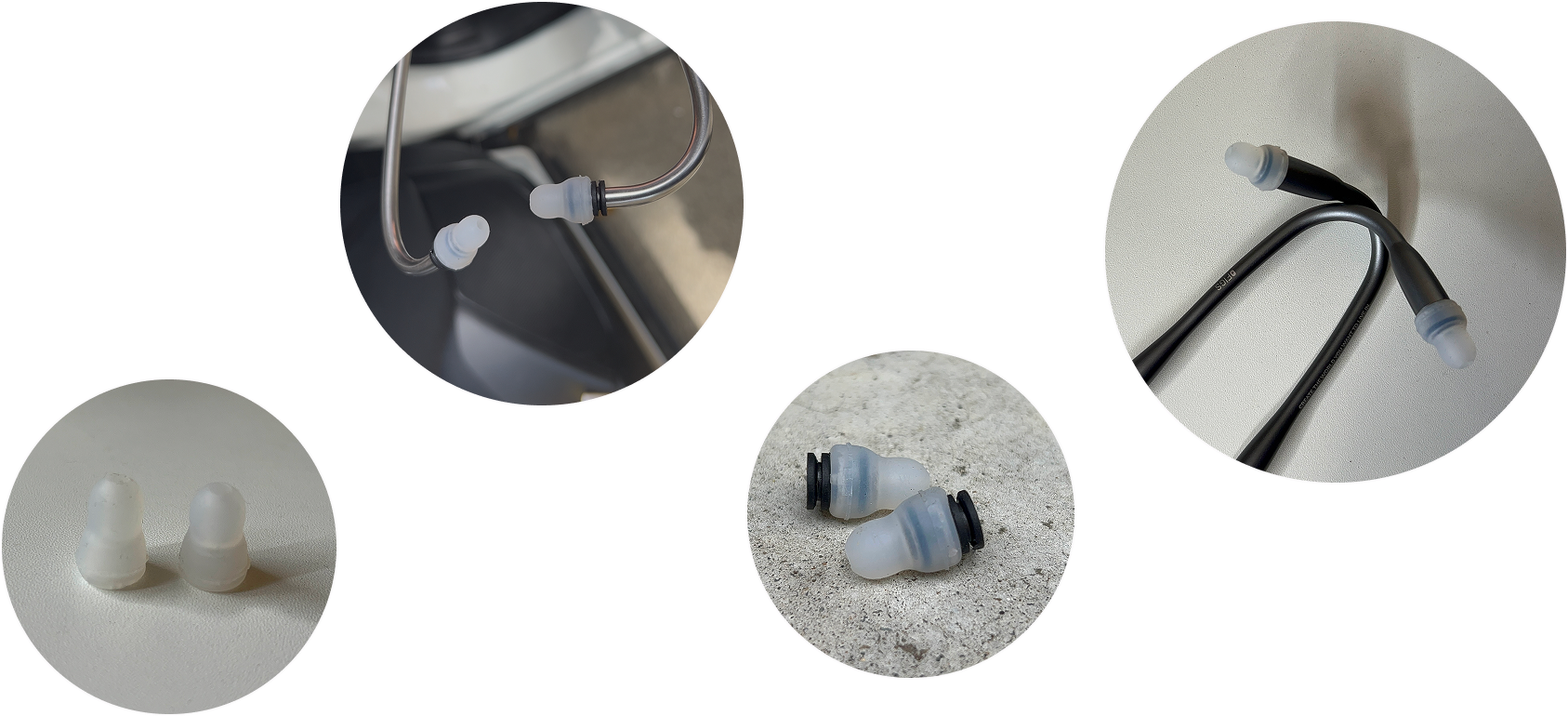

Team Designs: Iteration 2

Team Design: Iteration 3

Testing: Sensitivity from Bode Plots

Acoustic Seal Frequency Response

Final Design

Limitations

The cost required to manufacture our design with the final material prohibited us from creating a prototype similar to the original ear tip

Asynchronous work made it challenging to receive molds and prototype with quick turnaround.

Access to 3D models of ear anatomy would have allowed us to ensure better geometry to enable more effective sealing.

Key Takeaways

When designing a product in a competitive market, aesthetics and Industrial Design becomes a need rather than a luxury in design

Anthropometric measurements are good design criteria, however after testing, further adjustments will be needed due to subjectivity.

Understanding how a single design element interacts with other components is essential to ensuring a cohesive and functional product.